Leak control (Flotest)

Tools for control

Flotest is a check bench for any subassembly based on a functioning principle with no seal as pumps 2 ans 3 pieces, rotative distributor, rotative or sliding sluice gate.

This check bench is used routinely within SPC to control 100% of the systems without seal delivered to our customers

This bench will allow you to manage your pump park, thanks to pumps checks which permit you to :

- Consider the necessary leak to the good functioning of a pump without seal

- Follow the wear of sliding or rotative surfaces

- Detect parasite leaks

The Flotest functioning principle is to analyse the pressure drop in the check element at a given time

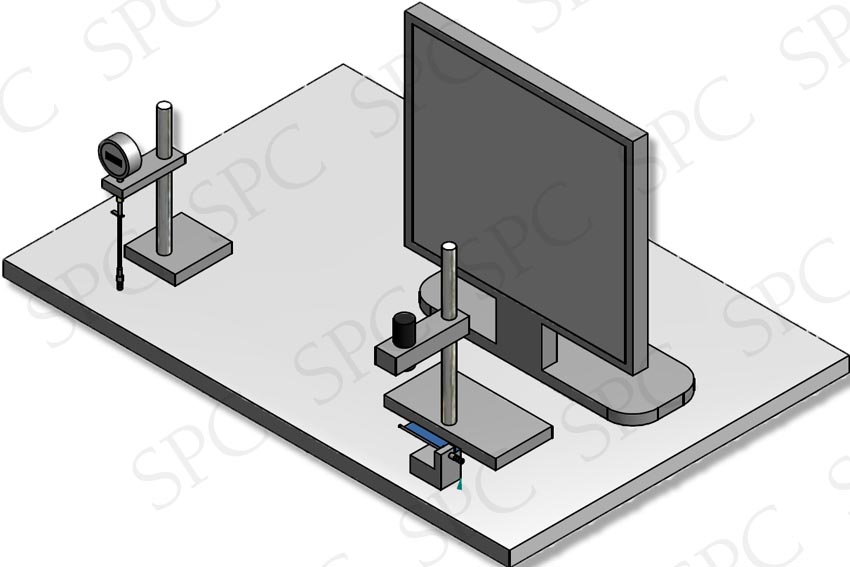

The whole of checking is in two parts :

- An immersion tank equipped with a support necessary to hold the pump during the procedure

- A control bay gathering the industrial computers, datalogger ( which integrates pneumatic management and leak detection ) and Flotest software

The FLOTEST software allows to store checks made in order to make a monitoring of the pumps park. It can be connected to a factory network, to a storage server for the data back-up. The software can manage access levels and in option responds to the FDA 21CFRP11 standard.

- Risk decrease of pumps jammings

- Risk decrease of particular redrop generated by pumps

- Allows preventive maintenance of your pump park

- Easy use

- Possibility to check all pumps without seal in the market

Liste des applications liées à ce produit :

- Pumps with no seal

- Preventive maintenance

- Subassembly with no seal

- Management of pumps park

- Assemblies for elements maintenance to check in the immersion tank

- Traceability software / pumps park management

- Access traceability and actions according to the FDA 21CFRP11 standard