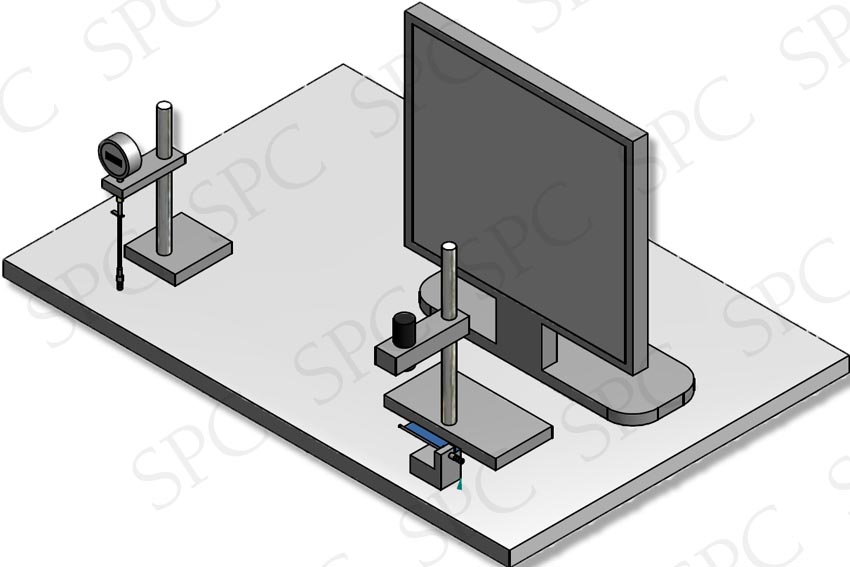

Slidind check bench for pump without seal

Tools for control

" The observation of the defects appearance allows [...] to avoid stopping lines and to anticipate maintenances "

The jamming or the capping of pumps without seal is in most the consecutive events to an impact or another deformation on the sliding surfaces of the pump.

The observation of these defects arrival allows, in lots of cases, to avoid stopping lines and to anticipate pumps maintenances before it's too late.

To help you in the in situ disgnostic and to enable you to make regular checks of your pumps park, SPC Engineering has developed a sliding check bench of pumps.

Indeed, the arrival of defects on sliding surfaces of pumps go with a change of quality of the piston sliding or the bushel in the pump cylinder

Our bench performs in real time a control of the resistant force to the sliding during a movement itself controlled digitally.

A pressure gauge continuously examines this effort and retransmits it to the men-machine interface, allowing to determine if the pump is true or not.

The bench can perform many control rushes and, dependind to the options chosen, these checks can be automatically achieved at different angular values.

This machine is delivered independent, ready to be used, with its certification CE.

Construction

The bench conception, with attachments quickly interchangeable, allows the use of this one for all your pumps park even if you have production lines of different manufacturers.

The system is entirely in digital control. The control recipes, depending on the type of control, are saved at the men-machine interface. So, an instant start-up of the control is possible, without having to perform a lot and tedious adjustments.

As with all these other digital control machines, SPC Engineering designed the system and open way with user-centric ergonomics. Thus, all the necessary parameters to create new recipes will be available for you and will drive you autonomous.

For example, you can change races, speed, acceleration and deceleration, and the instructions of the pumps rejections.

Basically, the system has a rejection function conform / not conform according to a maximal effort order configured in recipes.

In option, the system can handle the editing and sending to a printer a report integrating the effort curve of the controlled pump. Moreover, with an optional configuration more advanced, these curves can be saved in a database for a future consultation.

- Digital control system

- Table top construction easy to install

- Easy to use

- Quick change of attachments depending on the type of pump to control

Applications linked to this product :

- Pumps with no seal

- Distributors with no seal

- User management following access levels

- Controls Traceability and the events following the CFR21P11 standard

- The machine is delivered autonomous, ready to use, with its CE certification

- Creation / printing of the control report