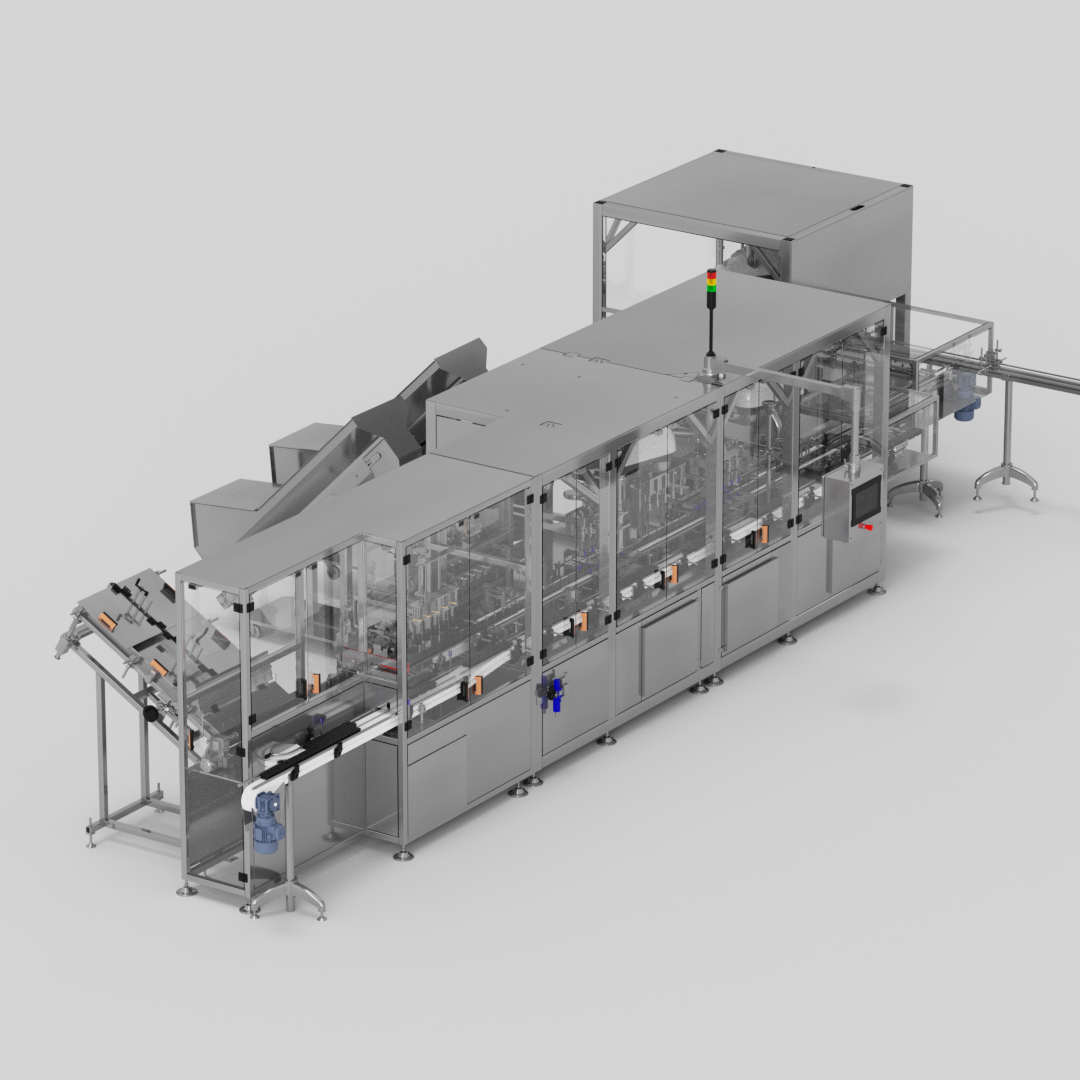

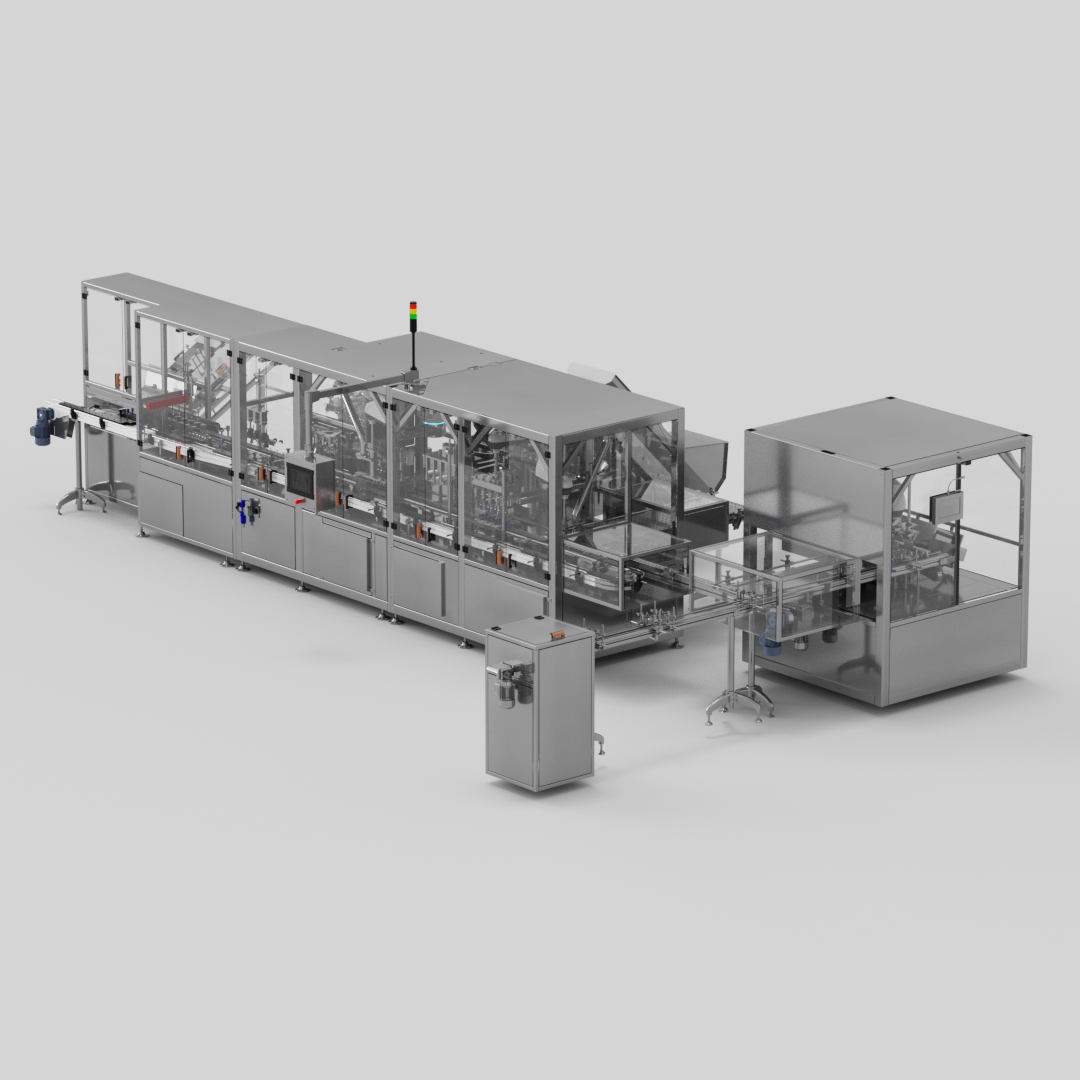

Packaging line for dropper pipettes

COMPLETE LINES

A versatile solution designed to meet your production requirements.

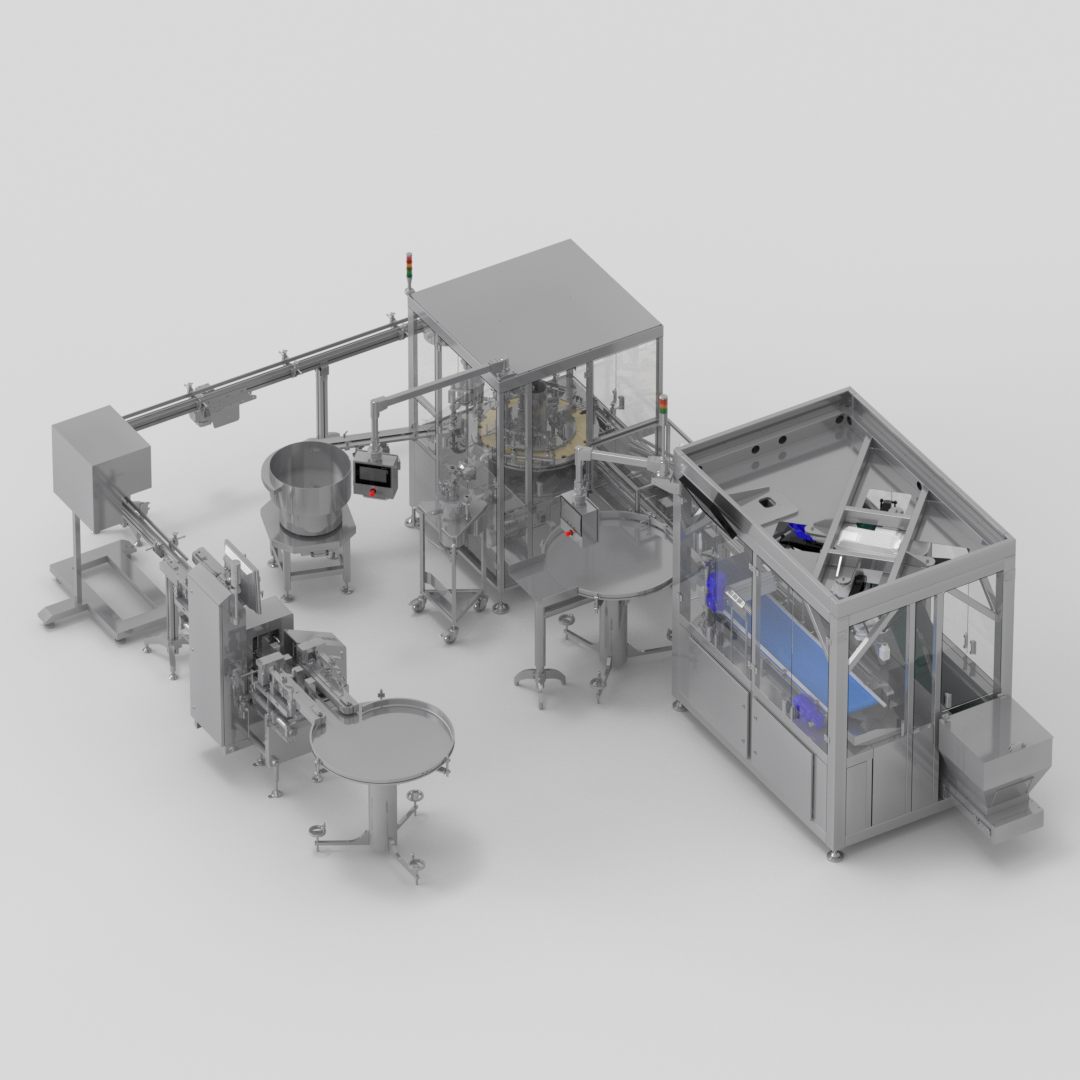

This solution, originally developed for dropper bottles distributed in bulk, encompasses several functions around which we are able to develop multiple options:

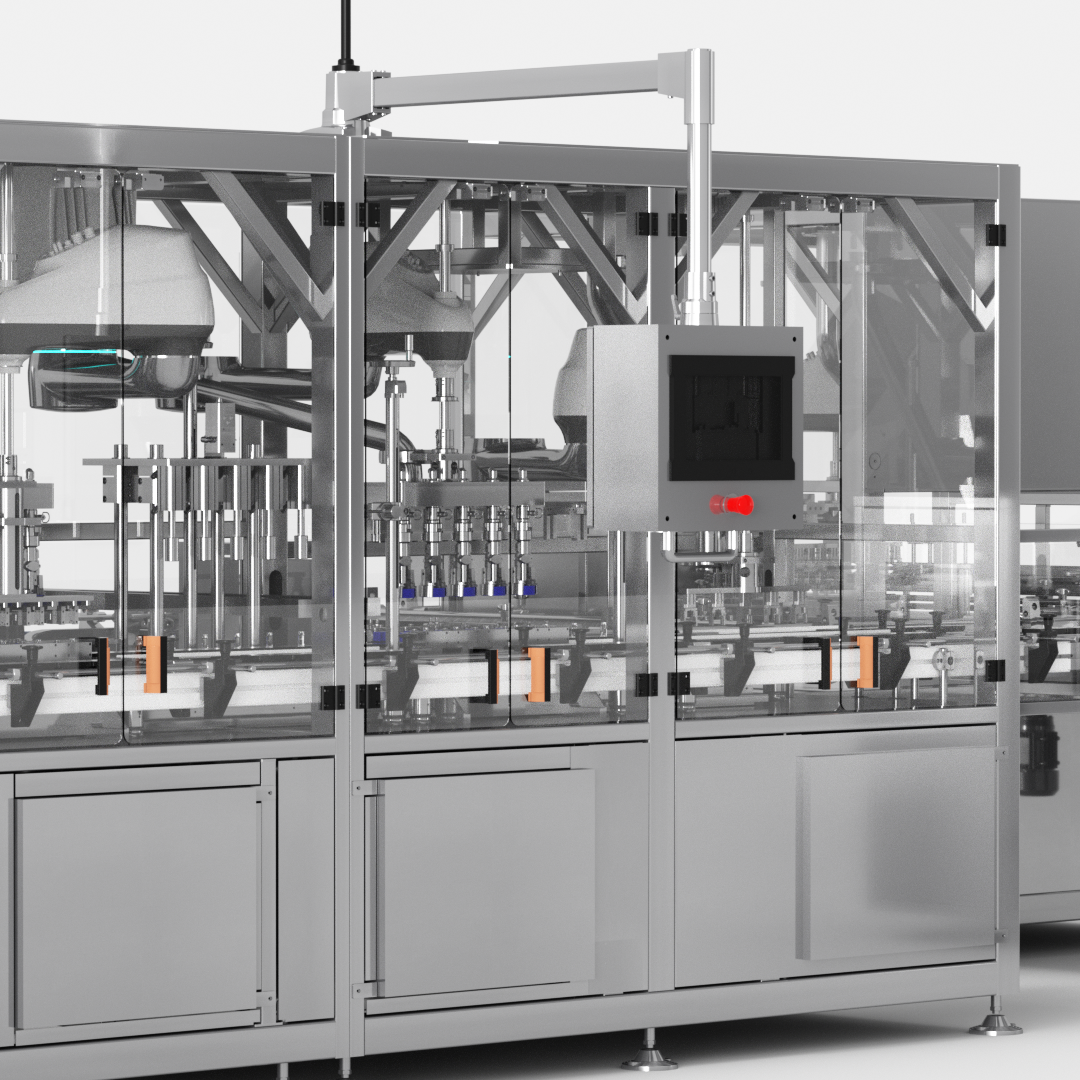

- Filling (Volumetric/Peristaltic/Poids/Flowmeter)

- Capping - Sealing - Crimping

- Labeling (banding / licking)

- Identification (laser/inkjet)

- Final conformity check (Vision/Weight)

Ideal for :

The pilgrim-step conveying system combined with the robots not only enhances reliability and speed, but also limits human contact and, consequently, the risk of cross-contamination.

In addition to being able to adapt to the requirements of an aseptic environment, our packaging line can be designed to produce multiple formats on the same line (multi-formats).

Liste des applications liées à ce produit :

- Gel

- Waterlike

- Suspensions

- Creams

- Syrup

Our tailor-made design enables us to adapt our solution to your production constraints and expectations.

- Manual or semi-automatic infeed for nest or bulk containers

- Vacuum or inert gas filling

- Volumetric, peristaltic, flowmeter or weight dosing

- Vacuum or mechanical capping - Screwing - Crimping

- Labelling - Inkjet marking - Laser marking

- Robotic or mechanical conveying

- Compatible with several container formats (quick format changes)